Key parameters include pH, total alkalinity, calcium hardness, and sanitizer levels. Best pool installer nashville TN. "Adding a spa to your pool area can transform it into a relaxing retreat. "Regular pool inspections are crucial for maintaining a safe and functional swimming environment. Best nashville pool builders TN. Vinyl pools are usually the most affordable upfront, but periodic liner replacements add to long-term expenses.

Each option has its pros and cons, so homeowners should weigh the initial costs, long-term maintenance, and water quality benefits before making a decision." By choosing a seasoned professional, you increase the likelihood of a successful, well-executed pool installation."

Routine inspections of heaters, chlorinators, and automation systems help catch potential issues early.

"Residential and commercial pools differ significantly in size, usage patterns, and regulatory requirements. By retrofitting your pool with these modern technologies, you enhance its functionality and make day-to-day management easier and more cost-effective."

Educating all pool users on safe behavior-such as no running on wet surfaces and no diving in shallow areas-further reduces risks. Highlighting a valid pool warranty in your home listing demonstrates that the pool has been well-maintained and professionally cared for." best pool company Nashville TN. "Pool safety codes can vary significantly depending on the region, reflecting differences in climate, local regulations, and community priorities. Installation begins with choosing the right spa size and type-either built-in or freestanding-based on your available space and budget.

However, they may require more frequent liner replacements, adding to long-term costs. A properly cared-for cover prevents debris, dirt, and contaminants from entering the water, reducing the workload on your filtration system.

The contractor will typically review your property's layout, assess any site-specific challenges, and suggest potential designs that suit your space and lifestyle. Renovated pools also signal that the property is well-maintained, boosting buyer confidence. Consulting with a professional can help ensure you choose a system that meets your specific needs." "There are various pool types to consider, each offering unique features and benefits.

Although fiberglass pools have fewer customization options than concrete, their durability and cost-effectiveness make them a smart investment for many homeowners looking for a long-lasting, easy-to-maintain pool." Commercial pools, on the other hand, require daily attention to ensure water quality, frequent chemical testing, and consistent inspection of safety equipment.

"Selecting a qualified pool renovation contractor is critical for a successful project. While both types of pools can benefit from periodic resurfacing and equipment upgrades, the more intensive use and regulatory demands on commercial pools often result in a shorter overall lifespan."

A service technician will typically inspect the equipment or structure to confirm the issue is covered under the warranty terms.

Additionally, if you lack the time or knowledge to maintain your pool effectively, scheduling regular professional service can help keep your pool in top condition without added stress."

Using a thermal pool cover at night prevents heat from escaping, while also reducing evaporation. "Vinyl pools have become a popular option among homeowners due to their affordability, versatility, and smooth surface. Keeping the pump's motor and seals in good condition by inspecting them periodically and lubricating O-rings will help prevent costly repairs. To avoid surprises, it's important to budget for contingencies, get detailed estimates, and maintain open communication with your contractor throughout the project."

"Modern energy-saving pool equipment includes variable-speed pumps, high-efficiency heaters, LED lighting, and advanced automation systems. "Certain pool features are well worth the investment when upgrading.

By taking care of your pool cover, you'll protect your pool and make maintenance easier year-round." While these upgrades improve functionality, aesthetics, and convenience, it's essential to factor them into your overall pool budget.

Smaller pools, such as plunge or cocktail pools, are better suited for limited spaces or those who prefer a more intimate setting.

"Preventing leaks and damage in your pool requires routine inspections and timely repairs. In regions with freezing temperatures, winterizing the pool is essential. Permit fees, inspections, and landscaping adjustments might also increase expenses.

A plunge pool (or plunge basin or waterfall lake) is a deep depression in a stream bed at the base of a waterfall or shut-in. It is created by the erosional forces of cascading water on the rocks at the formation's base where the water impacts.[1] The term may refer to the water occupying the depression, or the depression itself.[2]

Plunge pools are formed by the natural force of falling water, such as at a waterfall or cascade; they also result from man-made structures such as some spillway designs.[3] Plunge pools are often very deep, generally related to the height of the fall, the volume of water, the resistance of the rock below the pool and other factors.[4] The impacting and swirling water, sometimes carrying rocks within it, abrades the riverbed into a basin, which often features rough and irregular sides. Plunge pools can remain long after the waterfall has ceased flow or the stream has been diverted. Several examples of former plunge pools exist at Dry Falls in the Channeled Scablands of eastern Washington.[5] They can also be found underwater in areas that were formerly above sea level, for example, Perth Canyon off the coast of Western Australia.

Plunge pools are fluvial features of erosion which occur in the youthful stage of river development, characterized by steeper gradients and faster water flows. Where softer or fractured rock has been eroded back to a knickpoint, water continues to bombard its base. Because this rock is often less resistant than overlying strata, the water from the higher elevation continues eroding downward until an equilibrium is achieved.

A somewhat similar bowl-shaped feature developed by flowing water, as opposed to falling water, is known as a scour hole. These occur both naturally and as a result of bridge building.

|

This article needs additional citations for verification. (July 2010)

|

Salt water chlorination is a process that uses dissolved salt (1000–4000 ppm or 1–4 g/L) for the chlorination of swimming pools and hot tubs. The chlorine generator (also known as salt cell, salt generator, salt chlorinator, or SWG) uses electrolysis in the presence of dissolved salt to produce chlorine gas or its dissolved forms, hypochlorous acid and sodium hypochlorite, which are already commonly used as sanitizing agents in pools. Hydrogen is produced as byproduct too.

The presence of chlorine in traditional swimming pools can be described as a combination of free available chlorine (FAC) and combined available chlorine (CAC).[1] While FAC is composed of the free chlorine that is available for disinfecting the water, the CAC includes chloramines, which are formed by the reaction of FAC with amines (introduced into the pool by human perspiration, saliva, mucus, urine, and other biologics, and by insects and other pests).[2] Chloramines are responsible for the "chlorine smell" of pools, as well as skin and eye irritation. These problems are the result of insufficient levels of free available chlorine, and indicate a pool that must be "shocked" by the addition of 5–10 times the normal amount of chlorine.[1] In saltwater pools, the generator uses electrolysis to continuously produce free chlorine. As such, a saltwater pool or hot tub is not actually chlorine-free; it simply utilizes added salt and a chlorine generator instead of direct addition of chlorine. It also burns off chloramines in the same manner as traditional shock (oxidizer). As with traditionally chlorinated pools, saltwater pools must be monitored in order to maintain proper water chemistry. Low chlorine levels can be caused by insufficient salt, incorrect (low) chlorine-generation setting on the SWG unit, higher-than-normal chlorine demand, low stabilizer, sun exposure, insufficient pump speed, or mechanical issues with the chlorine generator. Salt count can be lowered due to splash-out, backwashing, and dilution via rainwater.

Research has shown that because saltwater pools still use chlorine sanitization, they generate the same disinfection byproducts (DBPs) that are present in traditional pools. Of highest concern are haloketones and trihalomethanes (THMs) of those the predominant form being bromoform. Very high levels of bromoform—up to 1.3 mg per liter, or 13 times the World Health Organization's guideline values—have been found in some public saltwater swimming pools.[3]

Manufacturers have been producing saltwater chlorine generators in the United States since the early 1980s, and they first appeared commercially in New Zealand in the early 1970s (the Aquatech IG4500).[4]

The chlorinator cell consists of parallel titanium plates coated with ruthenium and sometimes iridium. Older models make use of perforated (or mesh) plates rather than solid plates. Electrolysis naturally attracts calcium and other minerals to the plates. Thus, depending on water chemistry and magnitude of use, the cell will require periodic cleaning in a mild acid solution (1 part HCl to 15 parts water) which will remove the buildup of calcium compound crystals, such as calcium carbonate or calcium nitrate. Excessive buildup can reduce the effectiveness of the cell. Running the chlorinator for long periods with insufficient salt in the pool can strip the coating off the cell which then requires an expensive[clarification needed] replacement, as can using too strong an acid wash.

Saltwater pools can also require stabilizer (cyanuric acid) to help stop the sun's UV rays from breaking down free chlorine in the pool. Usual levels are 20–50 ppm. They also require the pH to be kept between 7.2 and 7.8 with the chlorine being more effective if the pH is kept closer to 7.2. The average salt levels are usually in the 3000-5000 ppm range, much less than the ocean, which has salt levels of around 35,000 ppm.[5] In swimming pools, salt is typically poured across the bottom and swept with the pool brush until it dissolves; if concentrated brine is allowed into the return-water system it can cause the chlorinator cell to malfunction due to overconductivity.

Salt water chlorination produces an excess of hydroxide ions, and this requires the frequent addition of hydrochloric acid (HCl, also known as muriatic acid) to maintain pH.[6]

The benefits of salt systems in pools are the convenience and the constant delivery of pure chlorine-based sanitizer. The reduction of irritating chloramines versus traditional chlorinating methods and the "softening" effect of electrolysis reducing dissolved alkali minerals in the water are also perceived as benefits. For some people that have sensitivities to chlorine, these systems may be less offensive.

Disadvantages are the initial cost of the system, maintenance, and the cost of replacement cells. Salt is corrosive and will damage some metals and some improperly-sealed stone. However, as the ideal saline concentration of a salt-chlorinated pool is very low (<3,500ppm, the threshold for human perception of salt by taste; seawater is about ten times this concentration), damage usually occurs due to improperly-maintained pool chemistry or improper maintenance of the electrolytic cell. Pool equipment manufacturers typically will not warrant stainless steel products damaged by saline pools. Calcium and other alkali precipitate buildup will occur naturally on the cathode plate, and sometimes in the pool itself as "scaling". Regular maintenance of the cell is necessary; failure to do so will reduce the effectiveness of the cell. Certain designs of saline chlorinators use a "reverse-polarity" method that will regularly switch the roles of the two electrodes between anode and cathode, causing this calcium buildup to dissolve off the accumulating electrode. Such systems reduce but do not eliminate the need to clean the electrolytic cell and the occurrence of calcium scale in the water.

As chlorine is generated, pH will rise causing the chlorine to be less effective. Many systems with chemistry automation can sense the rising pH and automatically introduce either CO2 or hydrochloric acid in order to bring the pH back to the target level.Automation systems will also manage levels of sanitizer by monitoring the ORP or redox levels of the water. This allows only the needed amount of chlorine to be generated based on the demand.

Sodium bromide can be used instead of sodium chloride, which produces a bromine pool. The benefits and downsides are the same as those of a salt system. It is not necessary to use a chloride-based acid to balance the pH. Also, bromine is only effective as a sanitizer, not as an oxidizer, leaving a need for adding a "shock" such as hydrogen peroxide or any chlorine-based shock to burn off inorganic waste and free up combined bromines. This extra step is not needed in a sodium chloride system, as chlorine is effective as both a sanitizer and an oxidizer. A user would only need to "super chlorinate" or increase chlorine production of the cell occasionally. That would normally be less than once a week or after heavy bather loads.

They do an outstanding job installing beautiful pools and transforming backyards. Winston is exceptional, his communication is top-notch, and he ensures every detail is perfect. Highly recommend!

Winston Farzan has done excellent work for me several times. He's been able to tackle many different jobs at once. I save jobs for him knowing that I can depend on his expertise!

Awesome. I watched a small backyard turn into a backyard oasis. The other options for a smaller pool were either fiberglass or refurbished containers. This is an actual concrete pool with automation. Looks great and I love it!

Professional installers ensure that the pool is properly leveled, securely installed, and complies with local codes. They also handle permits and can provide warranties for peace of mind.

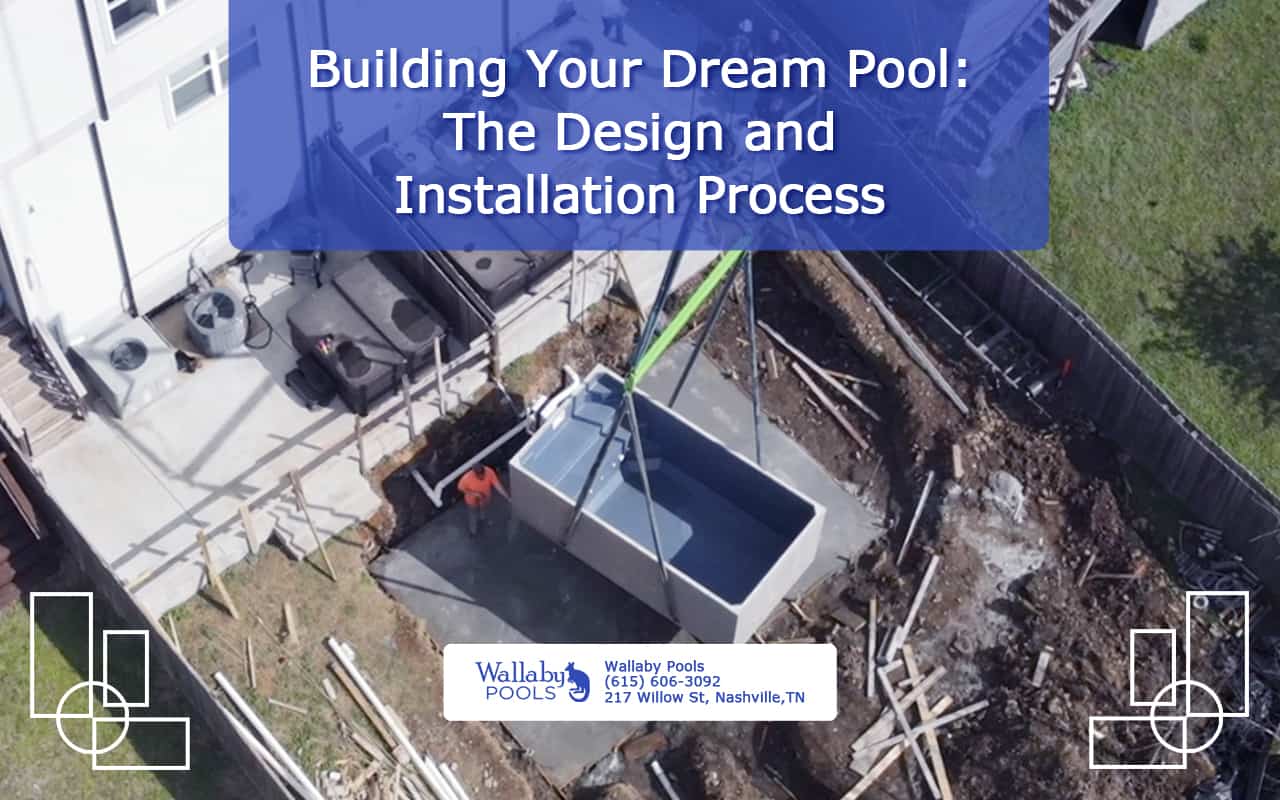

Nashville pool builders typically handle the entire pool construction process, including design, excavation, installation, and finishing touches like decking and landscaping. They also offer maintenance and repair services.

Fiberglass pools are a great choice in Nashville due to their quick installation, durability, and low maintenance needs. They are well-suited for local climates and offer long-lasting enjoyment.

The price depends on the size, shape, and features, but fiberglass pools in Nashville generally start around $35,000 and can go up depending on customization and installation complexity.

Costs vary based on pool size, material, and added features like lighting or waterfalls. Site preparation, local permits, and labor expenses also impact the final price.

The timeline depends on the pool type. Fiberglass pools can be installed in as little as a few weeks, while concrete pools may take several months. A reliable contractor will provide a clear schedule.