Regularly inspecting and servicing equipment ensures that it operates efficiently and prevents costly breakdowns. "Estimating the total cost of building a pool requires considering multiple factors beyond just construction. Best pool installer nashville TN. "Pool warranty claims can be denied for a variety of reasons, often related to maintenance or improper use. The higher usage volume of commercial pools demands more robust filtration systems, larger pumps, and frequent chemical adjustments.

Additionally, choosing premium materials or adding features like a spa or waterfall can quickly escalate costs. Best nashville pool builders TN. While the liners may need periodic replacement, advancements in materials have improved their longevity and durability.

Planning your renovation in stages or shopping around for competitive quotes can also help manage costs. "Keeping an eco-friendly pool requires a focus on sustainable practices and ongoing care.

As temperatures cool, reducing pump run times and using a pool cover can help keep debris out and minimize evaporation.

By keeping the water warmer for longer periods, pool covers reduce the need for continuous heating and lower energy consumption. Vinyl-lined pools have the lowest initial costs, but liner replacement expenses can add up over time. Monitor water levels regularly-unexpected drops could indicate a leak that needs immediate attention. "Finding the right pool contractor involves evaluating their experience, reputation, and communication skills.

Installing a pool lift or ramp can also help accommodate those with limited mobility. best pool contractor Nashville,TN. Regularly brush and vacuum the pool surface to remove debris that could scratch or weaken the material.

"The decision between vinyl and concrete pools comes down to cost, maintenance, and aesthetic flexibility. During peak swimming season, skimming, vacuuming, and balancing water chemistry should be done regularly.

"To keep your pool liner or surface in excellent condition, it's important to follow a few key maintenance tips.

Include additional expenses for permits, inspections, and landscaping. best pool company Nashville TN.

"Pool renovations enhance the aesthetics, functionality, and efficiency of your outdoor space, which can increase the overall value of your property. Freeform designs often blend seamlessly with lush, organic surroundings, while geometric shapes complement modern or minimalist yards. Upgrading to a variable-speed pump reduces energy consumption and allows for more precise control over filtration cycles. These warranties typically cover issues such as structural defects, equipment malfunctions, and premature wear.

Additionally, shade-providing trees can help regulate pool water temperature, reducing the need for excessive heating. Start by contacting the contractor or manufacturer and providing documentation such as the original invoice, warranty agreement, and photos of the problem.

By following these maintenance steps, homeowners can enjoy a clean, energy-efficient pool that remains gentle on the environment."

Automatic covers prevent water loss through evaporation, and advanced filtration systems help minimize the need for frequent backwashing. "Commercial pools require specialized design considerations to accommodate higher bather loads, comply with strict safety standards, and ensure durability. "Regular pool inspections help ensure that the pool and its associated equipment meet all safety requirements.

Investing in energy-efficient pumps, heaters, and LED lighting reduces utility bills. This detailed process ensures the pool is built to last, but it also requires skilled professionals and a longer timeline compared to other pool types." While fiberglass pools may not offer the same level of customization as concrete, their long lifespan and lower overall maintenance make them an appealing choice for many homeowners." Some warranties also cover structural elements, such as the pool shell or liner.

"While pool warranties offer valuable protection, they often have limitations. These systems are relatively low-maintenance, and once installed, the operational costs are minimal.

Regularly check and clean the filtration system to ensure optimal performance, and use natural or low-impact chemicals to maintain water balance. Replacing outdated equipment with energy-efficient models ensures easier maintenance and lower costs.

"Maintaining your pool cover is crucial for keeping your pool clean, safe, and efficient.

"Some of the most common pool problems include cloudy water, algae growth, and equipment malfunctions.

A hot tub is a large tub full of water used for hydrotherapy, relaxation or pleasure. Some have powerful jets for massage purposes. Hot tubs are sometimes also known as "spas" or by the trade name Jacuzzi.[1] Hot tubs may be located outdoors or indoors.

In contrast to a typical bathtub, a hot tub is designed to be used by more than one person at a time, with many models accommodating four or more people. Unlike baths, soaps and shampoos are not used in wet-jetted hot tubs (although they can be used in air-jetted hot tubs). Home hot tubs are often closer in construction to standard bathtubs, while the construction of a public hot tub often has more in common with a swimming pool, of which it can be considered a type.

The earliest hot tubs were calderas in which hot stones were placed to heat the water.[citation needed] Therma in Ikaria has been a very popular place particularly for hydrotherapy ever since the 4th century B.C.[2] The remains of wrecked marble bathtubs along with a prehistoric aqueduct that have been unearthed from this area bear ample testimony of the place's popularity in the ancient times.[2]

In 737 A.D., Japan's first onsen opened near Izumo, Shimane, and centuries later, the first ryokan (inns) were built, offering food, accommodations, and soaking tubs called ofuro.

In ancient Rome, there were three types of baths: Baths at home (balnea), private baths (balnea privata), and public baths (balnea publica). The practice of bathing was so engrained that the Roman legions, during their long occupations in foreign lands, built their own baths at mineral and thermal springs in the newly conquered lands. Examples are found all over Europe.[3]

In the 1940s, hot tubs began to appear in the US, inspired by the Japanese ofuro. Hydrotherapy pumps were introduced by Jacuzzi. Fiberglass shell hot tubs appeared around 1970 and were soon superseded by cast acrylic shells.

The plumbing of the hot tub consists of:

Hot tubs are usually heated using an electric or natural gas heater, though there are also submersible wood fire hot tub heaters, as well as solar hot water systems. Hot tubs are also found at natural hot springs; in this case, the water may be dangerously hot and must be combined with cool water for a safe soaking temperature.

Effective insulation greatly improves the energy efficiency of a hot tub. There are several different styles of hot tub insulation: some manufacturers fill the entire cabinet with foam, while others insulate the underside of the shell, the inside of the cabinet, or both. Many manufacturers advertise the superiority of their approach to insulation, but few independent side-by-side comparisons are available. The hot tub pump and hot tub heater represent most of the power consumption in a hot tub and vary in use of power depending on their size.[4]

Energy efficiency of portable hot tubs has been studied by the Pacific Gas and Electric Company (PGEC),[5] leading to industry responses[6] and interest from both the California Energy Commission and Natural Resources Canada.[citation needed] California's portable electric hot tub listing[5] include R values of thermal insulation, and standby watts.[7][8]

In 2019 an update to the ANSI standard for energy efficiency was approved. For the first time, this new standard increases the minimum energy efficiency level for portable spas and inflatable spas.[9][10] Hot tub covers have been shown to reduce most of the evaporative losses from the pool when not in use. With this component of heat loss being 70%,[11] a cover with even a small R-value is able to achieve as much as a 75% reduction in heating costs when used as opposed to leaving the water surface exposed.[12]

There are several different types of spa covers. Some covers are better for insulation and therefore are lighter on internal parts and energy efficiency. Some examples of covers are insulated, aluminum, rolling, or a tonneau.[citation needed]

Since some hot tubs are not drained after each use it is necessary to treat the water to keep it attractive and safe. It must be neither too alkaline nor too acidic, and must be sanitised to stay free of harmful microorganisms. Partly due to their high water temperatures, hot tubs can pose particular health risks if not regularly maintained: outbreaks of Legionnaires' Disease have been traced to poorly sanitized hot tubs.[13] Typically chlorine or bromine are used as sanitizers, but salt water chlorination is starting to become more common.

Sanitation can also be aided by a non-chemical ozonator.

For aesthetic reasons, and for the sanitizer to work properly, water should be neither too alkaline nor too acidic (low pH). The hardness level of the water, measured as the amount of dissolved calcium, is also important. Insufficient hardness can lead to corrosion and water foaming. The ideal range of calcium hardness levels in a hot tub or spa water should be between 150 and 250 ppm (parts per million)[citation needed]

Sitting in water above normal body temperatures can cause drowsiness which may lead to unconsciousness and subsequently result in drowning. The U.S. Consumer Product Safety Commission (CPSC) recommends that water temperatures never exceed 40 degrees Celsius (104 °F). A temperature of 37 degrees Celsius (100 °F) is considered safe for a healthy adult. Soaking in water above 39 degrees Celsius (102 °F) can cause fetal damage during the first three months of pregnancy.[19]

It is also recommended to install residual-current devices for protection against electrocution. The greater danger associated with electrical shock in the water is that the person may be rendered immobile and unable to rescue themselves or to call for help and then drown.[20]

Hot tubs and spas are equipped with drains that can create powerful suction and between 1980 and 1996, the CPSC had reports of more than 700 deaths in spas and hot tubs, about one-third of which were drownings to children under age five. In the same period 18 incidents were reported to the CPSC involving body part entrapment. To reduce the risk of entrapment, US safety standards require that each spa have two drains for each pump, reducing the amount of suction.[21] From 1999 to 2007 there were 26 reports to the CPSC concerning circulation entrapments hot tubs and spas, including three deaths.[22]

In 2001[23] and in 2012[24] the CPSC issued recalls for spa heaters which overheated and caused fires.

The Uniform Swimming Pool, Spa and Hot Tub Code is a model code developed by the International Association of Plumbing and Mechanical Officials (IAPMO) to govern the installation and inspection of plumbing systems associated with swimming pools, spas and hot tubs as a means of promoting the public's health, safety and welfare.[25]

Poorly sanitized hot tubs have been linked to a number of diseases, principally caused by facultative anaerobic bacteria. Such incidents include hot tub folliculitis and legionellosis.[26][27]

|

This article needs additional citations for verification. (July 2010)

|

Salt water chlorination is a process that uses dissolved salt (1000–4000 ppm or 1–4 g/L) for the chlorination of swimming pools and hot tubs. The chlorine generator (also known as salt cell, salt generator, salt chlorinator, or SWG) uses electrolysis in the presence of dissolved salt to produce chlorine gas or its dissolved forms, hypochlorous acid and sodium hypochlorite, which are already commonly used as sanitizing agents in pools. Hydrogen is produced as byproduct too.

The presence of chlorine in traditional swimming pools can be described as a combination of free available chlorine (FAC) and combined available chlorine (CAC).[1] While FAC is composed of the free chlorine that is available for disinfecting the water, the CAC includes chloramines, which are formed by the reaction of FAC with amines (introduced into the pool by human perspiration, saliva, mucus, urine, and other biologics, and by insects and other pests).[2] Chloramines are responsible for the "chlorine smell" of pools, as well as skin and eye irritation. These problems are the result of insufficient levels of free available chlorine, and indicate a pool that must be "shocked" by the addition of 5–10 times the normal amount of chlorine.[1] In saltwater pools, the generator uses electrolysis to continuously produce free chlorine. As such, a saltwater pool or hot tub is not actually chlorine-free; it simply utilizes added salt and a chlorine generator instead of direct addition of chlorine. It also burns off chloramines in the same manner as traditional shock (oxidizer). As with traditionally chlorinated pools, saltwater pools must be monitored in order to maintain proper water chemistry. Low chlorine levels can be caused by insufficient salt, incorrect (low) chlorine-generation setting on the SWG unit, higher-than-normal chlorine demand, low stabilizer, sun exposure, insufficient pump speed, or mechanical issues with the chlorine generator. Salt count can be lowered due to splash-out, backwashing, and dilution via rainwater.

Research has shown that because saltwater pools still use chlorine sanitization, they generate the same disinfection byproducts (DBPs) that are present in traditional pools. Of highest concern are haloketones and trihalomethanes (THMs) of those the predominant form being bromoform. Very high levels of bromoform—up to 1.3 mg per liter, or 13 times the World Health Organization's guideline values—have been found in some public saltwater swimming pools.[3]

Manufacturers have been producing saltwater chlorine generators in the United States since the early 1980s, and they first appeared commercially in New Zealand in the early 1970s (the Aquatech IG4500).[4]

The chlorinator cell consists of parallel titanium plates coated with ruthenium and sometimes iridium. Older models make use of perforated (or mesh) plates rather than solid plates. Electrolysis naturally attracts calcium and other minerals to the plates. Thus, depending on water chemistry and magnitude of use, the cell will require periodic cleaning in a mild acid solution (1 part HCl to 15 parts water) which will remove the buildup of calcium compound crystals, such as calcium carbonate or calcium nitrate. Excessive buildup can reduce the effectiveness of the cell. Running the chlorinator for long periods with insufficient salt in the pool can strip the coating off the cell which then requires an expensive[clarification needed] replacement, as can using too strong an acid wash.

Saltwater pools can also require stabilizer (cyanuric acid) to help stop the sun's UV rays from breaking down free chlorine in the pool. Usual levels are 20–50 ppm. They also require the pH to be kept between 7.2 and 7.8 with the chlorine being more effective if the pH is kept closer to 7.2. The average salt levels are usually in the 3000-5000 ppm range, much less than the ocean, which has salt levels of around 35,000 ppm.[5] In swimming pools, salt is typically poured across the bottom and swept with the pool brush until it dissolves; if concentrated brine is allowed into the return-water system it can cause the chlorinator cell to malfunction due to overconductivity.

Salt water chlorination produces an excess of hydroxide ions, and this requires the frequent addition of hydrochloric acid (HCl, also known as muriatic acid) to maintain pH.[6]

The benefits of salt systems in pools are the convenience and the constant delivery of pure chlorine-based sanitizer. The reduction of irritating chloramines versus traditional chlorinating methods and the "softening" effect of electrolysis reducing dissolved alkali minerals in the water are also perceived as benefits. For some people that have sensitivities to chlorine, these systems may be less offensive.

Disadvantages are the initial cost of the system, maintenance, and the cost of replacement cells. Salt is corrosive and will damage some metals and some improperly-sealed stone. However, as the ideal saline concentration of a salt-chlorinated pool is very low (<3,500ppm, the threshold for human perception of salt by taste; seawater is about ten times this concentration), damage usually occurs due to improperly-maintained pool chemistry or improper maintenance of the electrolytic cell. Pool equipment manufacturers typically will not warrant stainless steel products damaged by saline pools. Calcium and other alkali precipitate buildup will occur naturally on the cathode plate, and sometimes in the pool itself as "scaling". Regular maintenance of the cell is necessary; failure to do so will reduce the effectiveness of the cell. Certain designs of saline chlorinators use a "reverse-polarity" method that will regularly switch the roles of the two electrodes between anode and cathode, causing this calcium buildup to dissolve off the accumulating electrode. Such systems reduce but do not eliminate the need to clean the electrolytic cell and the occurrence of calcium scale in the water.

As chlorine is generated, pH will rise causing the chlorine to be less effective. Many systems with chemistry automation can sense the rising pH and automatically introduce either CO2 or hydrochloric acid in order to bring the pH back to the target level.Automation systems will also manage levels of sanitizer by monitoring the ORP or redox levels of the water. This allows only the needed amount of chlorine to be generated based on the demand.

Sodium bromide can be used instead of sodium chloride, which produces a bromine pool. The benefits and downsides are the same as those of a salt system. It is not necessary to use a chloride-based acid to balance the pH. Also, bromine is only effective as a sanitizer, not as an oxidizer, leaving a need for adding a "shock" such as hydrogen peroxide or any chlorine-based shock to burn off inorganic waste and free up combined bromines. This extra step is not needed in a sodium chloride system, as chlorine is effective as both a sanitizer and an oxidizer. A user would only need to "super chlorinate" or increase chlorine production of the cell occasionally. That would normally be less than once a week or after heavy bather loads.

They do an outstanding job installing beautiful pools and transforming backyards. Winston is exceptional, his communication is top-notch, and he ensures every detail is perfect. Highly recommend!

Winston Farzan has done excellent work for me several times. He's been able to tackle many different jobs at once. I save jobs for him knowing that I can depend on his expertise!

Awesome. I watched a small backyard turn into a backyard oasis. The other options for a smaller pool were either fiberglass or refurbished containers. This is an actual concrete pool with automation. Looks great and I love it!

Professional installers ensure that the pool is properly leveled, securely installed, and complies with local codes. They also handle permits and can provide warranties for peace of mind.

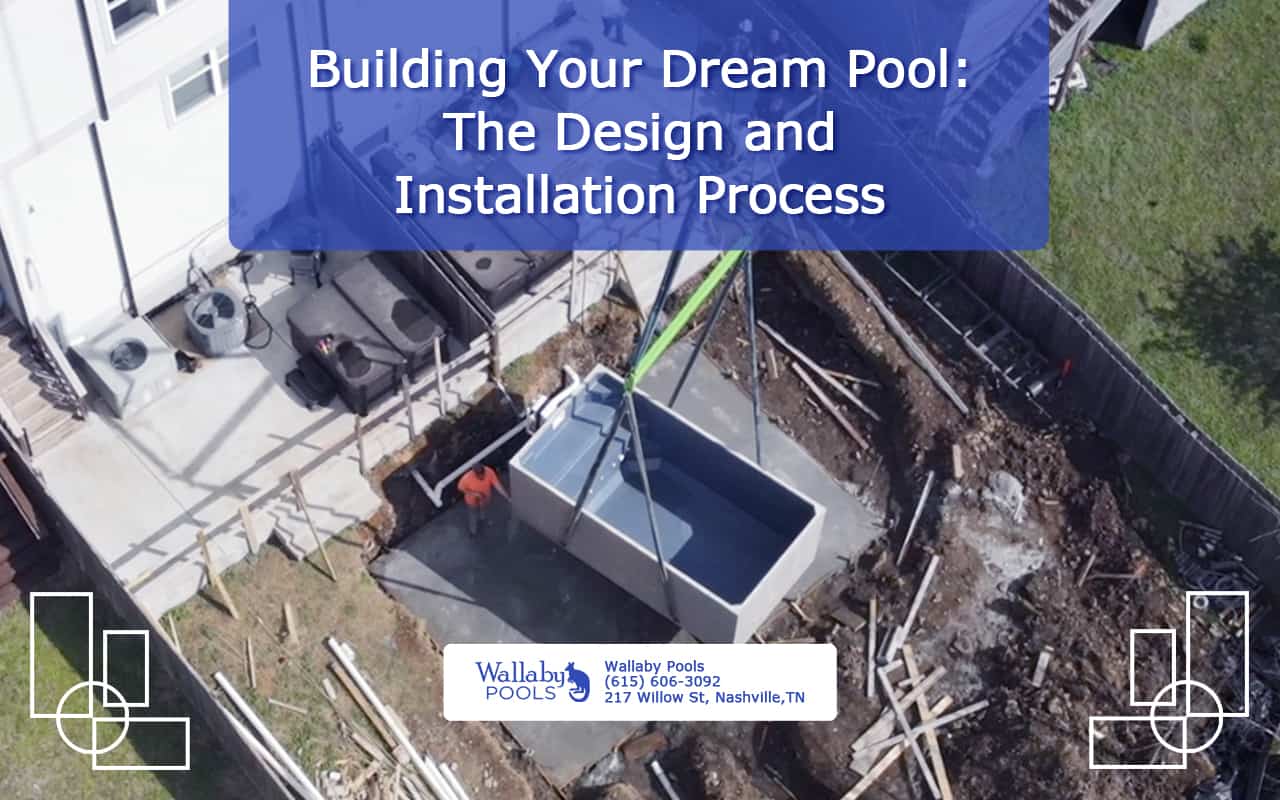

Nashville pool builders typically handle the entire pool construction process, including design, excavation, installation, and finishing touches like decking and landscaping. They also offer maintenance and repair services.

Fiberglass pools are a great choice in Nashville due to their quick installation, durability, and low maintenance needs. They are well-suited for local climates and offer long-lasting enjoyment.

The price depends on the size, shape, and features, but fiberglass pools in Nashville generally start around $35,000 and can go up depending on customization and installation complexity.

Costs vary based on pool size, material, and added features like lighting or waterfalls. Site preparation, local permits, and labor expenses also impact the final price.

The timeline depends on the pool type. Fiberglass pools can be installed in as little as a few weeks, while concrete pools may take several months. A reliable contractor will provide a clear schedule.